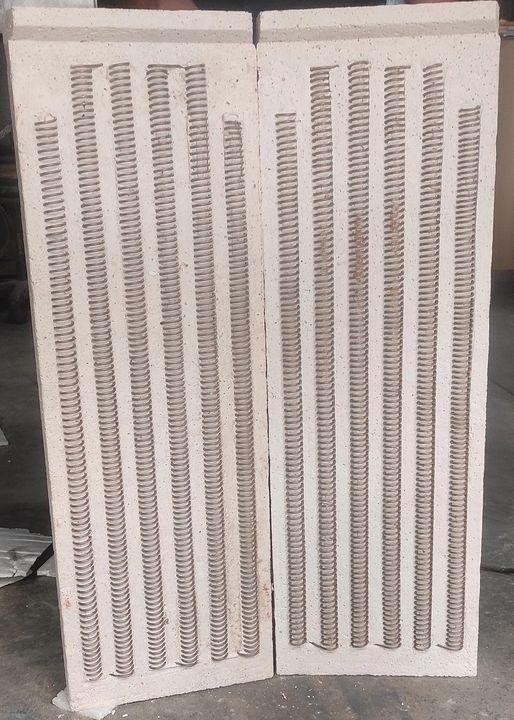

Kalyani's high power density heating elements are unsurpassed for melting aluminum and magnesium! Our next-generation Kalyani replacement heating elements feature improved life-enhancing materials technology. The dual-refractory system boosts power density and also increases operating life.

Important Features

• Newly redesigned heating elements feature maximum power density

• Highest aluminum and magnesium melting rates in the industry

• New life-enhancing materials technology and unique tooling system virtually eliminate internal stresses to maximize strength and shock resistance

• No compromises with the dual-refractory system:

(1) Rugged support panels made from the highest strength refractory with the best thermal properties, and

(2) Heater coil embedding cement contains no harsh chemicals so the element coil surface is never subjected to corrosive chemical attack as with single-refractory elements. Result: Greatly extended operating life

• Unique coil embedding process uses no paraffin or wax, eliminating harmful internal air gaps and hot spots that reduce element life

• Actual operating life as much as two to ten times longer than similar-appearing single-refractory elements

• Improved material properties reduce the internal temperature of embedded heater coils for the extended operating life

• Elements produced using highly automated equipment for higher quality, lower cost and reduced operator error

• Stranded lead-to-coil welds have by far the largest cross-sectional area in the industry, virtually eliminating weld failures.

Keywords

wax

Improved

paraffin

industry

hot spots

lower cost

coil welds

compromises

element life

weld failures

support panels

higher quality

harsh chemicals

shock resistance

Highest aluminum

internal stresses

Important Features

material properties

automated equipment

internal temperature

element coil surface

Actual operating life

Heater coil embedding

unique tooling system

embedded heater coils

maximum power density

dual-refractory system

reduced operator error

magnesium melting rates

best thermal properties

extended operating life

harmful internal air gaps

corrosive chemical attack

highest strength refractory

largest cross-sectional area

Unique coil embedding process

high power density heating elements

New life-enhancing materials technology

similar-appearing single-refractory elements

next-generation Kalyani replacement heating elements