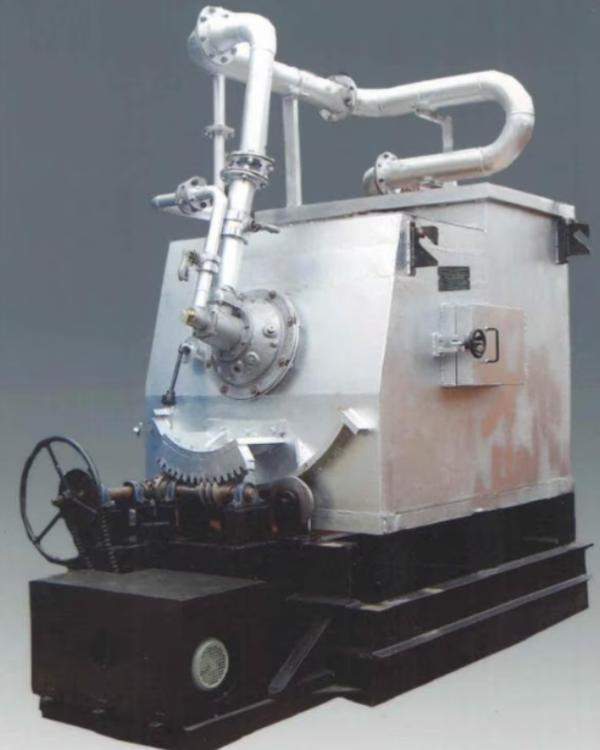

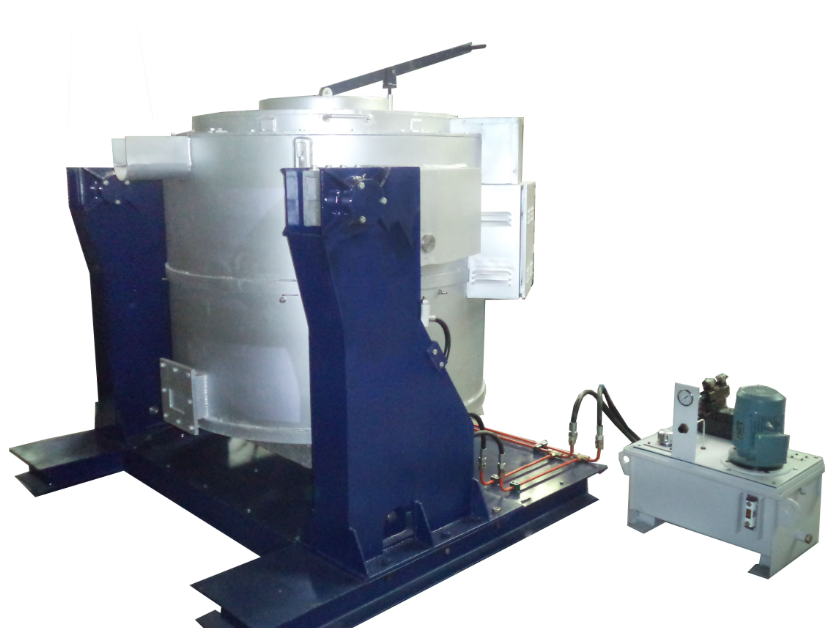

Aluminum melting furnace tilting type designs address a simple but important need—controlled pouring. Instead of relying on manual handling or external transfer systems, the tilting mechanism allows molten aluminum to be poured smoothly and precisely.

In Pune’s manufacturing setups, this approach often improves both safety and efficiency. Kalyani Furnaces India Pvt. Ltd builds tilting furnaces that balance mechanical stability with operator-friendly control. The tilting action reduces spillage risk and improves accuracy during metal transfer.

From a daily operations viewpoint, this matters more than it seems. Cleaner pours reduce metal loss, improve casting consistency, and make the work environment safer. Operators also benefit from reduced physical strain, which supports better long-term productivity.

Another advantage is flexibility. Tilting furnaces adapt well to different batch sizes and casting requirements. Whether the demand is small-volume precision or steady mid-scale production, the ability to control pour speed and angle makes a noticeable difference.

For facilities aiming to refine their aluminum handling process without adding unnecessary complexity, tilting furnaces offer a practical step forward.

Speak with Kalyani Furnaces India Pvt. Ltd in Pune to learn more about tilting furnace options.