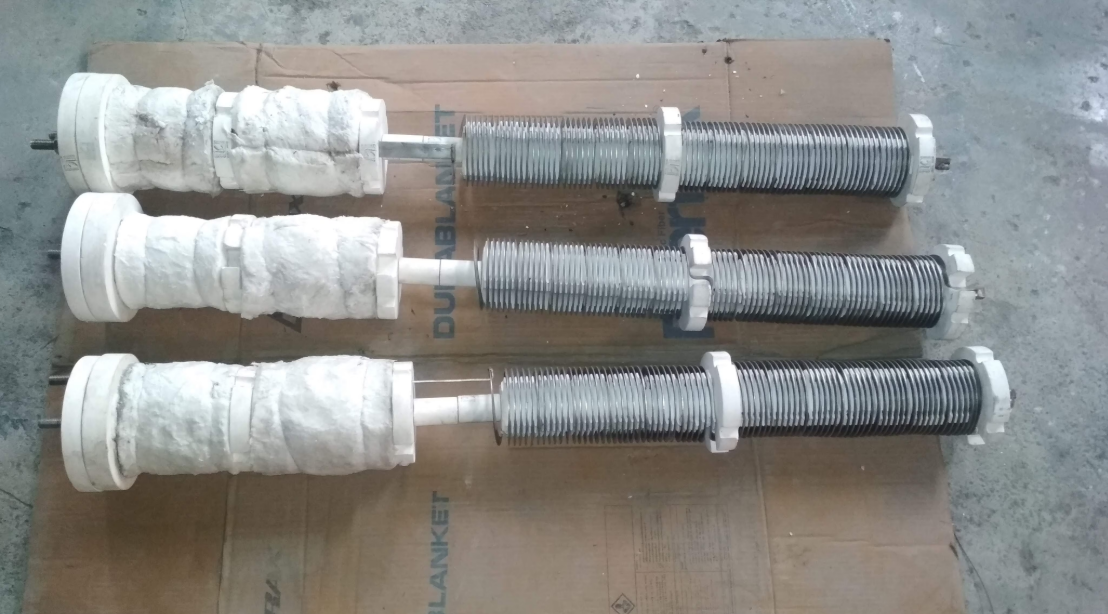

Edge Wound Bayonet Heater solutions are often chosen when consistency matters more than anything else. In aluminum melting and holding applications, even slight temperature instability can affect metal quality. That’s where a heater designed for controlled, even heat delivery quietly proves its value.

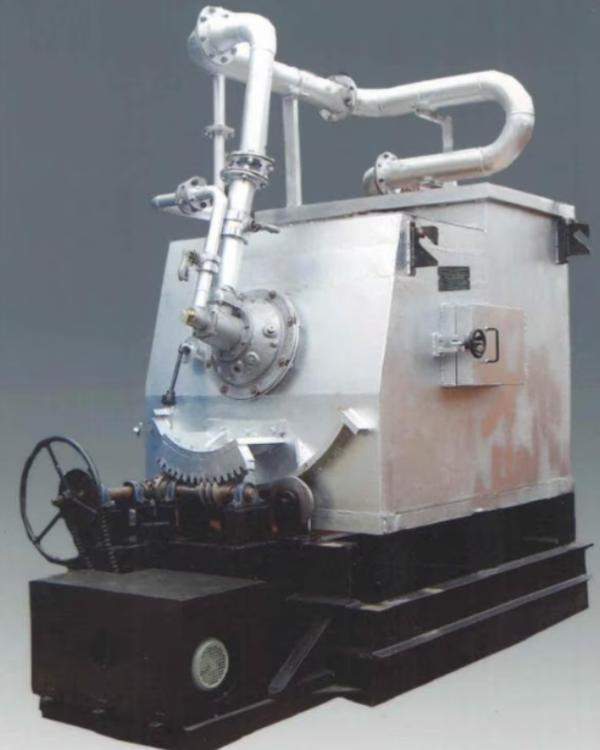

Kalyani Furnaces India Pvt. Ltd in Pune integrates edge wound bayonet heaters into furnace systems that demand long operating hours and predictable performance. The edge-wound construction allows efficient heat transfer while maintaining structural strength under repeated thermal cycles. This makes it suitable for continuous industrial use rather than short, intermittent runs.

From an operator’s perspective, these heaters offer a reassuring level of reliability. They warm up evenly, respond steadily to control inputs, and reduce the chances of localized overheating. Over time, this stability supports better melt consistency and lowers the risk of heater-related downtime.

Many production teams ask whether heater selection really influences process quality. In practice, it does. When heating elements perform consistently, process control becomes easier, outcomes become repeatable, and daily operations feel less reactive. It’s one of those components that rarely draws attention—until it’s missing.

For facilities focused on long-term efficiency rather than quick fixes, edge wound bayonet heaters quietly support dependable furnace operation.

To discuss suitable heater solutions, connect with Kalyani Furnaces India Pvt. Ltd in Pune.