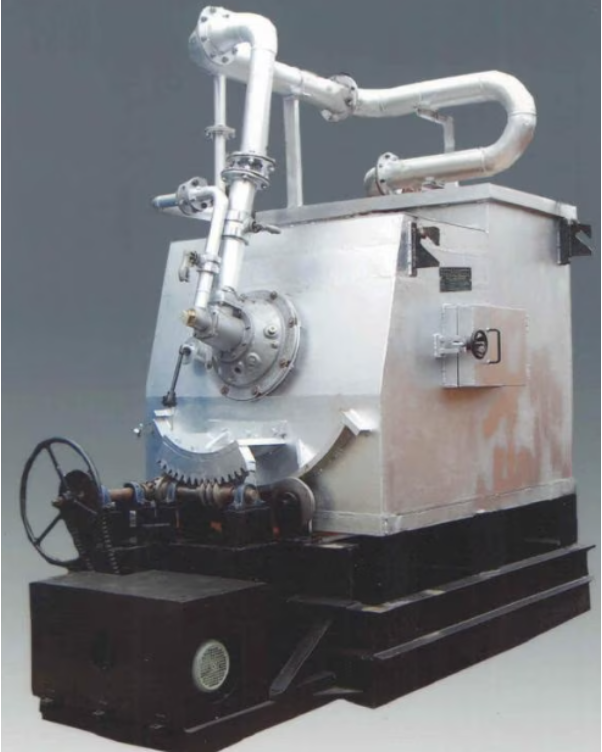

Aluminum melting Skelnar Furnace systems are valued for their ability to distribute heat evenly across the melt. In aluminum processing, uneven heating can lead to oxidation, temperature gradients, and inconsistent metal quality. A Skelnar design helps reduce these risks through controlled flame and heat circulation.

Manufacturers in Pune often rely on furnaces that can handle daily production demands without constant adjustments. Kalyani Furnaces India Pvt. Ltd designs Skelnar furnaces with a focus on thermal balance, insulation efficiency, and ease of operation. The result is a melting environment that feels stable rather than unpredictable.

One practical benefit of this furnace type is reduced operator intervention. When heat flow remains consistent, there’s less need for frequent temperature corrections. This not only improves productivity but also reduces stress on both equipment and personnel. Over long production cycles, those small efficiencies add up.

There’s also a quality angle. Consistent melting conditions help preserve aluminum chemistry, which matters in applications where casting precision is critical. When the melt behaves predictably, downstream processes tend to follow suit.

For aluminum processors looking for steady performance rather than dramatic claims, Skelnar furnaces offer a grounded, dependable solution.

To explore aluminum melting solutions, get in touch with Kalyani Furnaces India Pvt. Ltd in Pune.